What’s the Best Yeast for Pizza? A Complete Guide to Baker’s Yeast: Fresh vs Dry

Yeast is the ingredient that brings dough to life, quite literally. But what exactly is yeast? What is the difference between fresh and dry yeast? What are the advantages and disadvantages of each type, and is there one that is considered “better”? This article will answer all your questions about yeast

Note that the purpose of this article is to provide a general discussion about yeast, with a focus on the differences between fresh and dry yeast. If you want to learn the proper way to use yeast in dough, please refer to the article: How to Use Instant Yeast, Active Yeast, and Fresh Yeast Properly for Best Results.

What Is Yeast: Introduction

Yeast is a microscopic, single-celled organism. Although it is the simplest form of life, its activity in dough is significant and complex. Yeast is responsible for the most important process in yeast-leavened dough – the fermentation process – where a discussion of the fermentation process is often intertwined with the discussion on yeast activity. But what exactly is yeast?

Yeast is a type of fungus and belongs to the most basic group of organisms, along with fungi, algae, and bacteria. It’s a tiny organism that can only be seen under a microscope (don’t get confused – the yeast granules in dry yeast are simply many yeast cells “compressed” together). Yeast is present everywhere – in the air, in the soil, on plants, and practically anywhere around us. To survive, yeast requires sugar, water, and a warm environment.

Interesting fact: yeast is immobile and cannot move on its own, neither in nature nor in dough.

Like other types of fungi, yeast lacks chlorophyll, so it is unable to produce its own food (unlike plants that rely on chlorophyll for the process of photosynthesis to obtain nutrients). In other words, yeast depends on other organisms to provide it with food. This is where it connects to dough – for yeast to “work” in dough, meaning to ferment it, it requires a supply of food.

There are hundreds of yeast species in nature. Some can even be “captured” and used to make sourdough, but that’s a topic for another time. The yeast species that we refer to as baker’s yeast is called Saccharomyces cerevisiae, or S. cerevisiae for short, which roughly translates to “sugar fungus used in brewing”.

It is important to note that S. cerevisiae is the yeast species used for the production of all types of baker’s yeast, including both dry and fresh. In other words, all types of yeast are produced from the same species of yeast.

For further information on yeast activity in the dough, please refer to the following article: Pizza Dough Fermentation Process Explained: Understanding the Science Behind It

It is important to note that the flavor in the dough does not come directly from the yeast, but rather from the by-products of its activity, in combination with other processes that occur in the dough.

Baker’s Yeast: General Background

Although all types of baker’s yeast are produced from the same yeast species (S. cerevisiae), there are hundreds of different strains within this species. These strains have slightly different characteristics and are used for various purposes such as baking, research, and brewing.

When it comes to the strains used for baker’s yeast production, most of them have common characteristics. These characteristics include the sugars they consume, their reproductive methods, and their shape under a microscope.

However, the strains used for baker’s yeast production do differ in terms of their resistance to sugar and osmotic pressure (discussed in the following section), as well as their rate of reproduction. The specific characteristics of baker’s yeast as a final product depend on the chosen strain and the production method employed.

There are three types of baker’s yeast available to us as products:

- Fresh yeast, also known as compressed yeast or cake yeast (CY)

- Instant dry yeast (IDY)

- Active dry yeast (ADY)

Yeast and Osmotic Pressure

You can find general information on osmotic pressure on Wikipedia. In the context of yeast, osmotic pressure refers to the movement of water and nutrients into and out of the yeast cells through the cell membrane. This process directly affects yeast activity and, consequently, fermentation.

The osmotic properties of yeast cells allow them to regulate the movement of molecules in and out of their environment, which in this case is the dough. This mechanism controls the intake of nutrients and the release of metabolic by-products, such as alcohol and carbon dioxide (CO2). These by-products are essentially what we refer to as “fermentation”.

Yeast is sensitive to changes in osmotic pressure. As osmotic pressure in the dough increases, it negatively impacts yeast activity. Higher osmotic pressure causes water to be drawn out of the yeast cells, which slows down or restricts their activity. In simple terms, increased osmotic pressure reduces yeast activity, and the higher the osmotic pressure, the more significant the impact on yeast activity and fermentation.

High concentrations of sugar, salt, and other soluble substances in the dough increase osmotic pressure, which inhibits yeast activity. Generally, when sugar levels exceed 5% of the flour weight (in baker’s percentage), the yeast’s ability to ferment the dough begins to be impeded. The impact becomes more pronounced as the sugar concentration in the dough rises.

In the context of sugar, osmotic pressure has a more pronounced effect on yeast when exposed to monosaccharides such as glucose and fructose, as well as disaccharides like sucrose (table sugar). In contrast, maltose, a disaccharide found in malt powder, remains largely intact throughout most of the fermentation process, thereby having a less pronounced effect on osmotic pressure.

Yeast sensitivity to osmotic pressure varies among different strains. Some strains are more resistant to osmotic pressure and perform better in sweet doughs with high sugar levels. For example, Osmotolerant Instant Dry Yeast is a type of baker’s yeast specifically designed for sweet doughs and is available to home bakers, though it may be less commonly found in regular grocery stores.

Salt, like sugar, creates osmotic pressure in the dough. When the salt concentration exceeds 1.5%, it slows down yeast activity, which is actually one of the desired effects of adding salt to the dough. A detailed article on the role of salt in dough will be published in the future.

When making sweet doughs with a high sugar content (5% or higher), it is suggested to use a larger amount of yeast to “compensate” for the reduced yeast activity caused by osmotic pressure (unless using osmotolerant yeast).

How Baker’s Yeast Is Made

Some terminology before we continue:

“Gas production”: The yeast’s ability to produce gas in the dough, indicating its activity level. Higher gas production capacity means greater yeast activity.

“Stability”: How well the yeast maintains its potency during storage. Lower stability means the yeast loses its ability to ferment the dough more quickly.

“Moisture”: Refers to the water content in the yeast. “Moisture content” specifically means the amount of water present.

“Shelf life”: The duration for which yeast can be stored before its leavening power significantly decreases.

First, yeast is not actually ‘produced’ but rather ‘grown’ or ‘cultured,’ similar to an agricultural crop. The primary food source used to grow yeast is molasses, a byproduct of refining sugar cane or sugar beet juice into white sugar. Molasses is an economical source of sucrose, glucose, and fructose—sugars that yeast can use as food.

Before being used to feed the yeast, molasses is dissolved in water, sterilized, and ‘fortified’ with additional substances necessary for yeast activity. These include nitrogen, phosphorus, sulfuric acid, sodium carbonate, and various minerals like calcium and magnesium.

Yeast is grown under sterile and controlled laboratory conditions, with growth occurring in stages. Manufacturers can regulate the nature and composition of the yeast by carefully controlling growth conditions such as temperature, ventilation, and available nutrients.

General Process for Manufacturing/Cultivating Baker’s Yeast:

- Strain Selection: The yeast manufacturer selects a strain and collects healthy, vigorous yeast cells from it.

- Initial Culturing: The yeast is cultivated in tubes containing the necessary nutrients, allowing it to multiply.

- Scaling Up: The cultures are transferred from the test tubes to larger industrial containers, such as giant fermentation tanks or ponds, where the yeast grows to the required scale for commercial production.

- Separation: Once the yeast has consumed all the nutrients, it is separated from the liquid and other components using a centrifuge, which spins to separate the different elements.

- Purification: The yeast is washed again to remove any residual nutrients and then centrifuged once more to ensure maximum purity of the yeast cells.

- Yeast Cream: A liquid form of pure yeast cells, known as yeast cream (or liquid yeast), is obtained. Yeast cream contains about 15% yeast cells and 85% moisture and serves as the base for producing all other yeast products, whether dry or fresh.

- Further Processing: The yeast cream is either processed into specific yeast products or sold directly to bakeries.

In some regions, bakeries receive yeast cream directly from the manufacturer before it is further processed into fresh or dry yeast. This is particularly common for bakeries located near the yeast production facilities, as yeast cream’s high moisture content requires special transportation to prevent spoilage or contamination. Due to its high moisture content, yeast cream must be used promptly, making it most relevant to bakeries that can use it immediately.

With an understanding of how yeast cream is made, which is the base for all types of baker’s yeast, we can now explore the specific production methods for each type of yeast.

The Production of Fresh Yeast

The production of fresh yeast involves reducing the moisture content of the yeast cream obtained at the end of the yeast cultivation/production process:

- Concentration: The yeast cream is concentrated through methods like filtration with a rotary press or vacuum, which separates liquids from solids. This process produces a concentrated yeast form with reduced moisture content.

- Compression: The concentrated yeast is then compressed into blocks or “cakes,” commonly known as compressed or cake yeast. This fresh yeast has a lower moisture content and a higher concentration of yeast cells.

- Forming the Final Product:

- Rectangular Blocks: The yeast is compressed through a rectangular nozzle to form long, rectangular “sausage” shapes, which are then cut into cubes for final packaging. This results in the familiar cube-shaped fresh yeast.

- Granules: Alternatively, the yeast can also be crumbled into granules to create granulated fresh yeast, although this form is less commonly used.

The strains used for fresh yeast production, along with their growth conditions, often prioritize gas production over stability.

Fresh yeast typically contains around 70% moisture and 30% yeast solids (yeast cells).

The Production of Active Dry Yeast

Active dry yeast is one of the earliest forms of dry yeast, introduced in the 1940s. Its production process is as follows:

- Starting Material: The process begins with fresh yeast, typically obtained in block or “cake” form.

- Drying Process: Fresh yeast is dried to remove moisture, usually through air drying or other controlled methods. This produces a concentrated yeast product.

- Granulation: Once dried, the yeast is ground into granular form. These granules are irregularly shaped rather than perfectly spherical.

The strains selected for active dry yeast, along with the drying methods, are chosen to enhance stability and extend shelf life.

Active dry yeast typically contains around 8% moisture and 92% yeast solids (yeast cells).

The Production of Instant Dry Yeast

Instant dry yeast, introduced in the 1960s, is widely favored by both home and professional bakers for its convenience and efficiency. Its production process has similarities to that of active dry yeast but includes some distinct differences:

- Addition of Emulsifiers: During the production of instant dry yeast, an emulsifier, sorbitan monostearate (E491), is incorporated. This emulsifier aids in the effective absorption of water by the yeast, enhancing its rehydration and activity. Sorbitan monostearate is a standard ingredient in instant dry yeast.

- Addition of Ascorbic Acid: Ascorbic acid (vitamin C) is often added as a dough enhancer. It strengthens the dough, improving its structure and elasticity. As we will see later on, this addition is particularly beneficial for instant dry yeast, as it helps to achieve better dough consistency.

- Sieving Process: Instant dry yeast is sieved through finer mesh sizes compared to active dry yeast, resulting in more uniform and finer yeast granules.

- Drying and Concentration: After sieving, the yeast granules undergo additional drying processes to concentrate them further.

Instant dry yeast typically has a higher gas production capacity than active dry yeast, but is generally less potent than fresh yeast.

Instant dry yeast typically contains around 3% moisture and 97% yeast solids (yeast cells).

In addition to sorbitan monostearate (E491) and ascorbic acid, the ingredient list for instant dry yeast may include various dough enhancers and conditioners. It’s important to note that instant dry yeast does not contain preservatives or ‘harmful’ ingredients. The included components are necessary to ensure the yeast performs effectively and the dough achieves the desired results.

The long shelf life of instant dry yeast is not due to any added preservatives, but is instead a result of its low moisture content. Foods or substances with higher moisture levels tend to spoil more quickly, whereas dry yeast remains stable over time due to its minimal moisture.

Types of Baker’s Yeast: Characteristics and Differences of Fresh and Dry Yeast

So we know there are three types of baker’s yeast: fresh yeast, active dry yeast, and instant dry yeast, with the main difference between them is their moisture content. But what exactly distinguishes them from one another, and why is each type better suited for certain purposes and not for others?

Dry Yeast

The principle behind dry yeast is straightforward: once the yeast cells, which have been dried and dehydrated to a moisture content of 3-7%, absorb water, they reactivate, and function like “fresh” yeast cells. Essentially, after rehydration, there is no difference between the yeast cells of dry yeast and those obtained from fresh yeast (although there may be variations in their characteristics, as mentioned earlier, their activity in the dough is practically identical).

The following sections will discuss active dry yeast and instant dry yeast separately.

To fully understand this section, it is recommended to first read the section ‘Dry Yeast: Rehydration and Glutathione Release’ in the following article: How to Use Instant Yeast, Active Yeast, and Fresh Yeast Properly for Best Results.

In summary, all types of dry yeast require a rehydration phase during which they absorb liquids. If this rehydration process is not ideal, especially if the yeast comes into direct contact with cold water, the yeast cell membrane may not function properly. This can result in the release of essential components from the yeast cells into the dough, particularly glutathione. When glutathione enters the dough, it breaks down gluten bonds and weakens the dough.

Characteristics of Instant Dry Yeast

The primary difference between instant dry yeast and active dry yeast lies in the rehydration phase. Instant dry yeast, with its smaller granule size and more porous cell membrane, absorbs water more quickly. This allows it to begin working immediately in the dough without requiring activation before being added, which is why it’s called ‘Instant’.

It’s important to note that the ‘advantage’ of instant dry yeast – its more porous membrane, which allows for faster water absorption – can also be a disadvantage if not handled correctly. While quicker water absorption is beneficial, the increased porosity can lead to the unwanted release of components from the yeast cell. This can negatively affect the yeast’s activity and the dough overall. Therefore, when using instant dry yeast, it’s crucial to ensure proper rehydration and avoid adding it directly to cold water. For more information on the optimal use of dry yeast, please refer to the article linked at the beginning of this section.

Characteristics of Active Dry Yeast

Active dry yeast generally needs to be “activated” before being added to the dough, which is where it gets its name. This is due to its less porous cell membrane, larger granule size compared to instant dry yeast, and the absence of sorbitan monostearate. These factors contribute to a slower rehydration process, making activation crucial to ensure optimal yeast activity.

To properly activate active dry yeast, it should be suspended/dissolved in warm water at about 40°C/104°F for 10 minutes. This process allows the yeast to fully rehydrate and become active before it’s mixed with the other dough ingredients, ensuring it works effectively from the start.

While it is technically possible (though not recommended) to add active dry yeast directly to the dough without prior activation, this can significantly slow down the rehydration process. If active dry yeast is not fully activated beforehand, it may take longer to reach its full strength, which can delay the fermentation process.

This delay is particularly problematic in recipes requiring shorter fermentation times of just a few hours, as the yeast may not have sufficient time to become fully active.

Shelf Life and Storage of Dry Yeast (Active and Instant)

Dry yeast has a very long shelf life. According to manufacturer guidelines, instant dry yeast can last up to two years, while active dry yeast can last up to one year. However, with proper storage, dry yeast can maintain its leavening power for even longer than two years, with minimal loss of leavening power.

For unopened packages, dry yeast can be stored at room temperature, ideally not exceeding 27°C/80°F. Once opened, it’s best to store the yeast in a completely sealed container to minimize exposure to air and moisture, which can degrade its potency.

The best places to store dry yeast are in the fridge (especially in colder areas like the back or inside) or in the freezer, which is recommended for optimal shelf life.

It is important not to keep dry yeast at room temperature after it has been opened, as this can significantly shorten its shelf life and potency.

One efficient method for storing dry yeast is to keep it in its original packaging, which is typically made of aluminum. After opening, roll and fold down the top of the packaging until it touches the yeast to minimize the air inside, effectively resealing it (see picture below). Alternatively, transferring the yeast to another airtight container also works well.

With optimal storage, dry yeast can lose about 10% of its leavening power during the first year (after production), if the package remains unopened. However, once opened, the yeast may lose potency more quickly, depending on how it is stored.

Moisture is the main factor that affects the shelf life of dry yeast. It is crucial to avoid introducing any moisture or “wetting” the inside of the container or package where the yeast is stored.

Specifically, it’s important to avoid drastic temperature changes inside the container or package. For example, when a cold container is taken out of the fridge or freezer and exposed to room temperature, condensation can form inside. This occurs when warm air meets the inside of the cold container, resulting in water droplets that the yeast can absorb, shortening its shelf life.

To avoid this, you can use one of the following methods:

- Remove the container or package of yeast from the freezer or refrigerator, take out the required amount, reseal it, and immediately return it to the cold storage. This minimizes the risk of condensation inside the container, and is the recommended method.

- Alternatively, allow the container to reach room temperature before opening it. This way, you balance the temperatures, preventing condensation from forming inside.

By following these methods, you can easily extend the shelf life of your dry yeast to at least one year, and in practice much longer. Personally, I have a package of instant dry yeast that is three years old and still very much active.

Fresh Yeast

Characteristics of Fresh Yeast

As we have already seen, fresh yeast contains a lower concentration of yeast cells compared to dry yeast (about 30% in fresh yeast versus about 90% in dry yeast). However, fresh yeast has a higher gas production ability, meaning that if we use the same “amount” of yeast cells in the dough, the dough containing fresh yeast will typically rise faster.

This is due to the different strains used for cultivating fresh yeast, as well as the manufacturing processes of dry yeast, which inevitably damage the cells and their potency to some extent.

Furthermore, the yeast cells in fresh yeast are already in an active state, allowing them to start fermenting the dough immediately, without the need for rehydration. While this may not always have a significant practical effect, it’s a notable characteristic of fresh yeast.

In general, fresh yeast, with its superior leavening ability, tends to perform better in sweet doughs with high sugar levels. In other words, fresh yeast may be the preferred choice for making sweet doughs.

While fresh yeast has a higher leavening power compared to dry yeast, this difference can be easily mitigated by using a greater quantity of dry yeast to achieve similar yeast activity in the dough. As a result, the superior leavening ability of fresh yeast typically doesn’t hold much practical significance for most baking applications, since the desired results can be achieved with either type of yeast by adjusting the amount used

In terms of its impact on the dough, using fresh yeast results in zero to non-existent glutathione release (since fresh yeast does not undergo rehydration). Therefore, theoretically, using fresh yeast will produce the strongest dough among the different types of yeast.

When using instant dry yeast with added ascorbic acid, the resulting dough can be similar to or even identical in strength to that made with fresh yeast. This is because ascorbic acid strengthens the dough, effectively counterbalancing the weakening effect of glutathione released during the yeast’s rehydration process.

A significant advantage of using fresh yeast is its performance in frozen dough production. Unlike dry yeast, which may suffer cell damage during its manufacturing and drying processes, fresh yeast retains its cell structure. This intact cell structure allows fresh yeast to better survive freezing, resulting in superior activity after thawing compared to dry yeast.

For this reason, fresh yeast is the preferred choice for most, if not all, frozen dough producers and manufacturers. For more information on freezing pizza dough, please refer to the following article: How to Freeze Pizza Dough: Understanding the Optimal Freezing Process for Best Results.

Another notable difference between fresh and dry yeast is the concentration of lactic acid bacteria. Fresh yeast contains a higher concentration of lactic acid bacteria, approximately ten times more than dry yeast.

While this could theoretically have an effect on the flavor profile, as lactic acid bacteria significantly influence the flavor during long fermentation, in practice, the difference will not be noticeable. Even if it is noticeable, it would require long room temperature fermentation, rather than cold fermentation.

The use of fresh yeast is still relatively common in Europe, mainly due to logistical reasons and tradition. As we are about to see, fresh yeast has a very short shelf life, which requires optimal transportation conditions, such as refrigerated transportation and quick delivery from factory to bakery.

Europe has a significant number of fresh yeast producers located near bakeries and yeast consumers, and, along with an efficient logistics system that allows for fast and efficient transportation, fresh yeast continues to be a reliable option.

Shelf Life and Storage of Fresh Yeast

Due to its high moisture content, fresh yeast has a very short shelf life. It typically lasts about two weeks at room temperature (approximately 23°C/73°F) and up to two months when refrigerated (0-5°C/32-40°F), from the date of production.

Fresh yeast loses its potency quickly. Even under optimal storage conditions in an unopened package, it can lose around 10% of its leavening power within the first month. Afterward, its potency decreases significantly each week, and it generally loses its leavening power completely after about two months.

It’s important to note that fresh yeast begins to lose its effectiveness the moment it leaves the factory, even if stored properly. Factors such as transportation and storage conditions at the point of sale can further impact its quality. Exposure to high temperatures, even for a short period, can diminish its leavening power before it reaches the supermarket or our fridge.

Therefore, it is recommended to keep fresh yeast in the refrigerator, well -packed in its original packaging, and use it within two months of the production date (not the purchase date). As time passes, the leavening power of fresh yeast gradually decreases, so using the same amount of yeast after four weeks may not yield the same fermentation results as in the first week.

Avoid storing fresh yeast in the freezer, as the freezing process damages the yeast cells. The high moisture content causes ice crystals to form, which physically harms the cells and reduces their viability.

Converting Between Fresh and Dry Yeast

For a practical guide on converting between different types of yeast, including a detailed conversion chart, please refer to the following article: Yeast Conversion Chart: How to Convert Fresh Yeast to Dry Yeast (and Vice Versa).

How to Identify Each Type of Yeast

Identifying fresh yeast is simple – it typically comes in a cube shape, is stored in the fridge, and the label will clearly read “fresh yeast”.

For dry yeast, however, things can become a bit more complex.

Here is how to identify instant dry yeast:

- Label: Clearly states “instant”. Although this may seem obvious, some yeast products around the world do not specify the type of dry yeast on the package.

- Ingredients: Look for sorbitan monostearate (E491) and/or ascorbic acid (E300). Sorbitan monostearate will always appear in the ingredient list of instant dry yeast.

- Expiry Date: Should be two years from the date of manufacture.

- Instructions: The package will indicate that it can be added directly to flour, without needing activation in water.

- Shape: Instant dry yeast granules are thin and elongated, whereas active dry yeast granules are spherical (see picture below).

If the product meets most or all of these criteria (usually it will meet all), it is instant dry yeast.

There is an ongoing discussion about Caputo’s dry yeast (green packaging) regarding whether it is active or instant dry yeast. Although the package labels it as ‘Active dry yeast,’ it meets all the criteria for instant dry yeast mentioned above, which means it is instant dry yeast (which I have also confirmed with Caputo). The use of the term ‘active’ instead of ‘instant’ is purely for marketing purposes, as ‘instant’ may be perceived as ‘inferior.’

However, this yeast product frequently receives complaints about its quality. Some packages work well, while others contain dead yeast straight from the factory, indicating potential quality control issues. Therefore, it is recommended to avoid this product. Any other readily available instant dry yeast products will offer more reliable performance.

Dry Yeast vs Fresh Yeast: Final Comparison

If you have read other posts on PizzaBlab, you already know that the answer to the question “what is better” is usually “it depends.” However, in this case, the answer is quite clear for home bakers (and beyond).

First, let’s talk about active dry yeast. In short, there is no reason to prefer active dry yeast over instant dry yeast. Active dry yeast has a shorter shelf life, requires more handling, and generally offers no advantages that make it worth considering.

Therefore, the true “battle” is between instant dry yeast and fresh yeast.

Instant Yeast vs Fresh Yeast

First, it is important to note that both fresh yeast and instant yeast are produced from the same yeast species (S. Cerevisiae), with the differences between them being the strain and processing. These differences mainly affect stability (shelf life) and leavening power (gas production).

The type of yeast (fresh/dry) does not affect flavor, and when used correctly, the results will be virtually identical.

It is also important to note that fresh yeast is not truly “fresh,” but simply contains more moisture. Instant yeast does not contain any preservatives, and there should not be any health concerns when choosing between fresh and instant yeast, as it is completely irrelevant. There is nothing “unhealthy” about dry yeast.

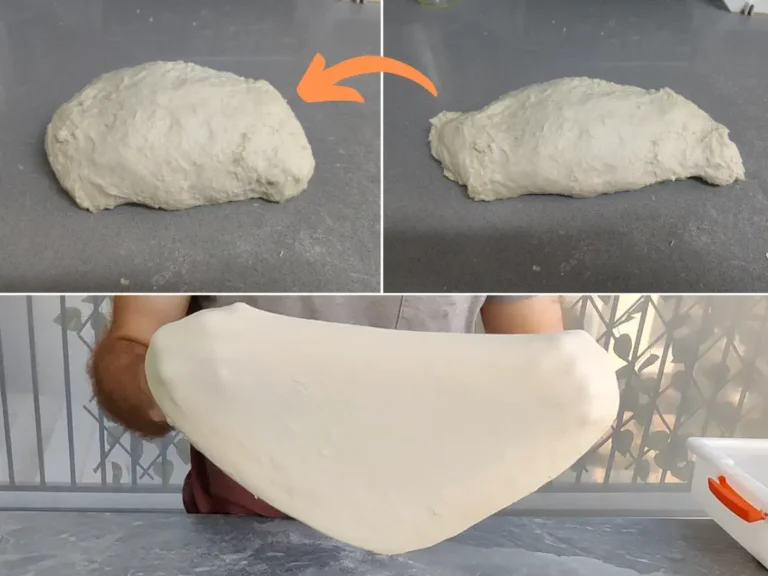

In terms of dough properties, instant yeast typically makes the dough more extensible (soft and ‘slack’) compared to fresh yeast, due to the inevitable release of glutathione. While this is desirable and even useful for pizza dough at normal levels of glutathione release, excessive glutathione release (such as when instant instant yeast is added directly to cold water) can lead to an overly extensible, weak, and sticky dough that is difficult to handle.

Broadly speaking, using instant yeast is preferable when making an “emergency dough” (dough that is fermented for just a few hours, typically 1-2 hours). This is because the very short fermentation may not allow the dough to “relax” and become sufficiently extensible (which depends on various factors, including the limited activity of the protease enzymes). The release of glutathione may aid in achieving a softer, less resistant dough that is easier to handle.

When it comes to frozen dough, fresh yeast is the clear winner. The intact yeast cells in fresh yeast survive freezing better than those in instant yeast and also result in less glutathione release, contributing to a frozen dough of better quality.

When it comes to shelf life, instant yeast wins by a knockout. This factor is crucial, especially for home bakers, as it is perhaps the most important parameter when comparing fresh and instant yeast.

Fresh yeast has a very short shelf life, lasting up to two months under optimal storage conditions. As time passes, fresh yeast significantly loses its leavening power, which can be measured in weeks or even days.

On the other hand, instant yeast has a much longer shelf life, lasting a year and typically much longer under optimal storage conditions, with minimal loss of leavening power.

If you bake frequently (i.e., on a daily basis) and can use an entire package of fresh yeast within a few weeks of purchasing it, fresh yeast might work well for you. However, for those who bake less frequently, instant yeast is the more practical choice.

In terms of ease of use, fresh yeast is slightly more convenient as it can be crumbled directly into the water or flour. Instant yeast may require more handling to ensure optimal function and to avoid negatively impacting the dough.

Economically, instant yeast is much more cost-effective choice for home bakers. It is roughly half the price of fresh yeast (varying depending on location) and is used in smaller quantities. Instant yeast is approximately six times cheaper than fresh yeast when considering both the cost and quantity needed. While this difference may seem small, it can become significant when using in large quantities.

In conclusion, unless you have a specific need for fresh yeast, instant dry yeast is generally the preferred option, and my personal recommendation as well.

For a guide on how to properly use and add yeast to dough, please refer to the following article: How to Use Instant Yeast, Active Yeast, and Fresh Yeast Properly for Best Results.

Enjoy the content on PizzaBlab? Help me keep the oven running!